The 2-Minute Rule for Sheroz Earthworks

Table of ContentsIndicators on Sheroz Earthworks You Need To KnowWhat Does Sheroz Earthworks Do?An Unbiased View of Sheroz EarthworksThe smart Trick of Sheroz Earthworks That Nobody is Talking AboutThe 8-Minute Rule for Sheroz Earthworks

For any type of earthwork contractor, it is essential to carry out work with quality, precision, and on timetable. Making use of equipment control in work makers allows maximizing the different stages in the earthwork process, from preparing to the upkeep phase - trimble tripod parts. The device control system helps the equipment driver in attaining the target aircraft rapidly and quickly

The maker control system guides the driver with centimeter accuracy. Remote support saves time and money, as it minimizes downtime in jobsites.

Fascination About Sheroz Earthworks

Our system's elements are carefully made to endure the harsh conditions of building and construction sites. Comparison of the very same task performed using equipment control versus the conventional technique discloses that, on average, the traditional method needs 50% even more time to achieve the exact same task as the technology-assisted technique.

Go into the Xsite machine control system; it's here to provide you with a considerable benefit when working with earthmoving machinery. Discover exactly how Xsite Device Control can boost your performance and make sure job safety and security! Xsite Maker Control systems can be installed to any kind of excavator from mini excavators to huge mining excavators.

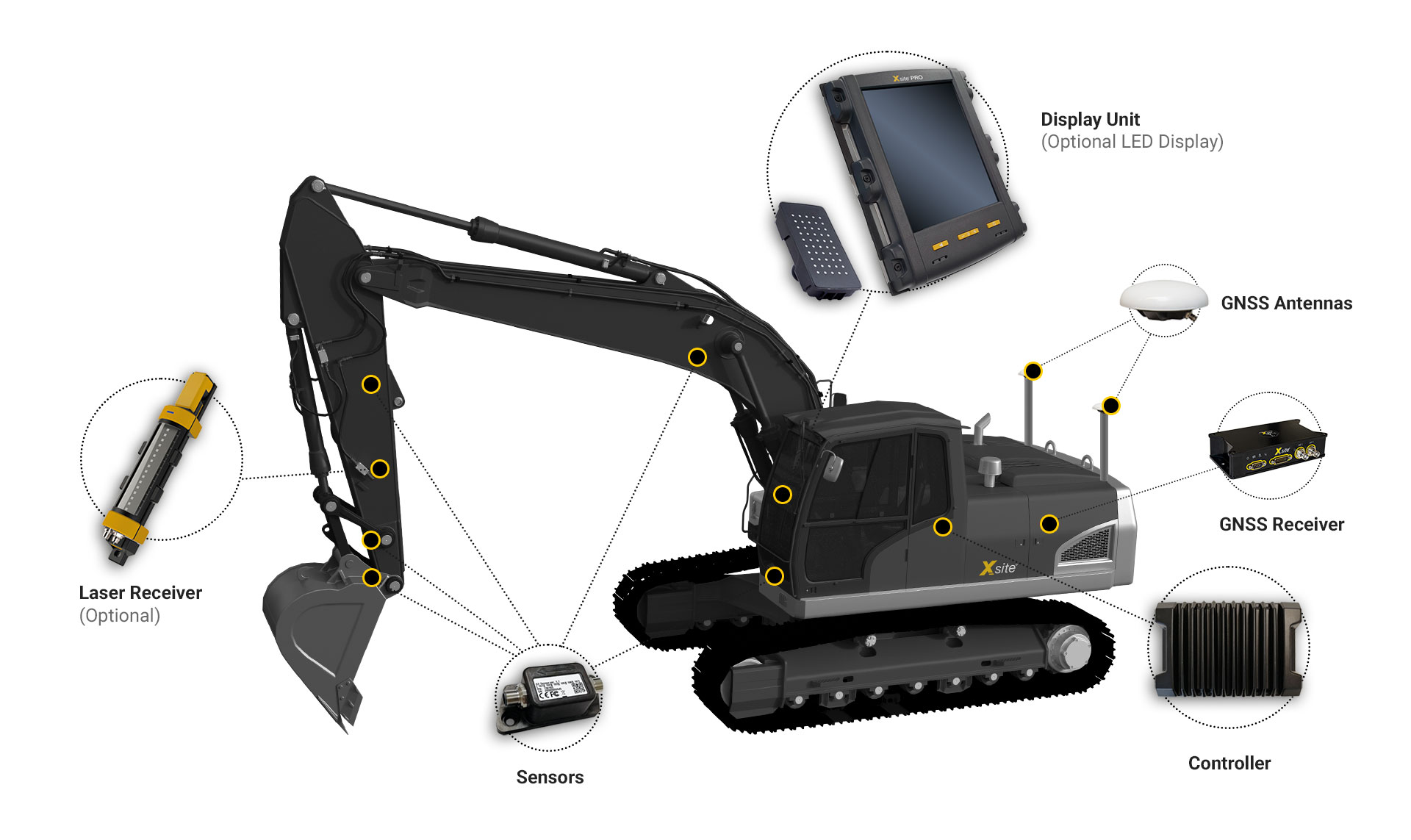

Exactly how does maker control work? In 2D systems, the device is outfitted with calibrated inclination sensing units. These sensors are placed on the pre-determined parts of the device in excavators the sensing unit are normally placed to the structure, boom (or booms), digger arm and to the fast coupler - trimble parts. By utilizing the information received from these sensors the system can determine the specific setting of the excavators container idea in importance to a referral point.

The system is extremely simple to discover the fundamentals can be shown in under one hour of training. How does the remote support job? A wireless internet connection makes it feasible to develop a remote link in between the machine control system and the solution.

Not known Details About Sheroz Earthworks

What sort of information styles Xsite systems assistance? Xsite Equipment Control systems sustain open basic data styles, allowing seamless info flow from one system to an additional. Sustained data formats: 2D-Maps: DXF Factor documents: DXF, XML, GT, CSV, KOF, PXY Geometry lines: VGP, SBG, XML, Anpakke Surface Area Designs: DXF, XML What parts are set up on my device? Depending on your selection of system (with or without placing, i.e - topcon., 2D or 3D), your equipment is outfitted with disposition sensors, a controller device, and a display/operating panel.

Numerous software and hardware services exist to assist identify an equipment's existing setting on the earth and contrast it with a preferred design surfaceand building and construction operators can do even more to take advantage of the benefits. Maker control is using different positioning sensing units and a display to provide the driver with a reference in between the setting of the pail or blade and the target grade.

Relying on the setup, machine control systems can supply the driver with a basic visual overview to pail or blade setting, or can instantly relocate the blade to grade best site by speaking with the machine's hydraulics - https://www.artstation.com/floydoverbeck1/profile. There are maker control systems readily available for nearly any kind of machine: graders, dozers, excavators, dirt and asphalt compactors, scrapes, leaners, crushing equipments, and pavers

Sheroz Earthworks - Questions

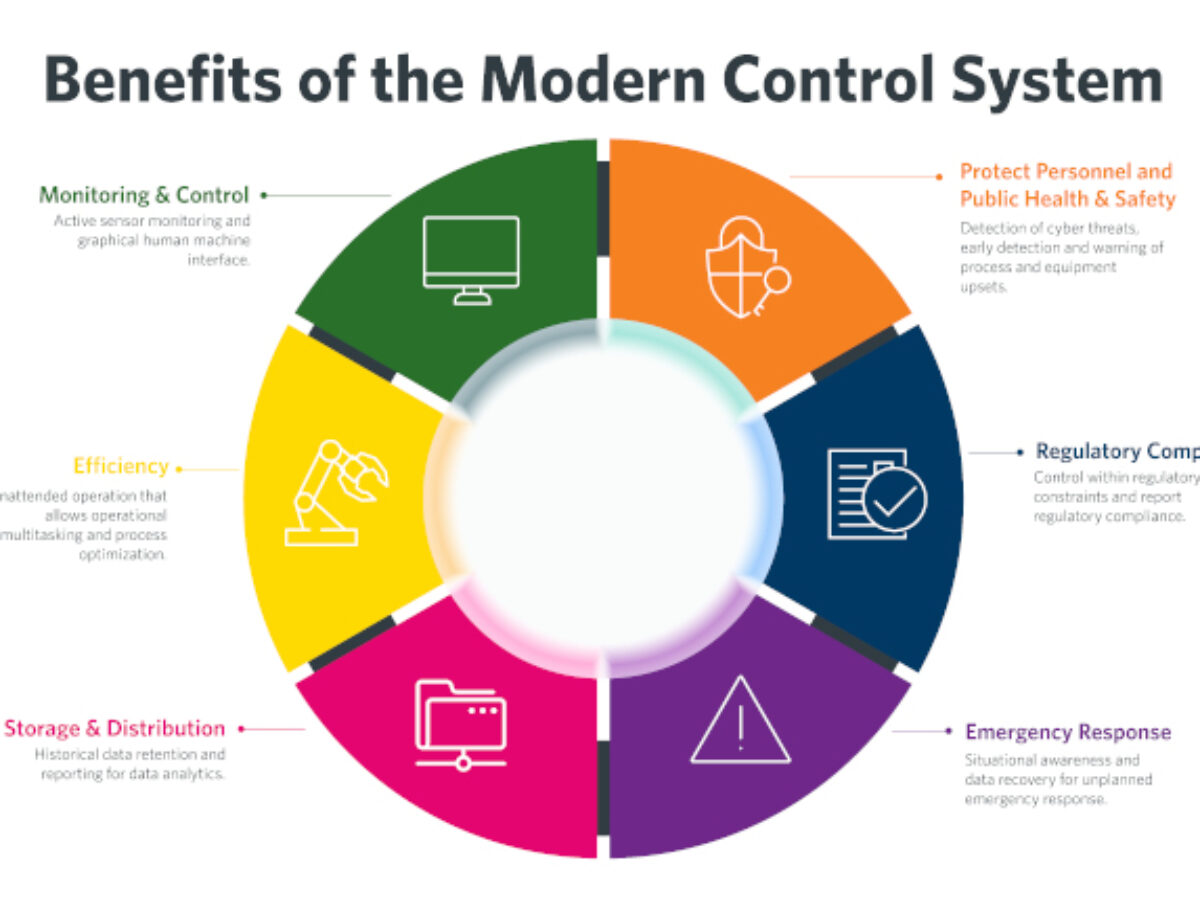

Some benefits include lowered rework, improved task performance, and reduced checking prices. Machine control can additionally assist increase performance and minimize total costs. This innovation is transforming the way the building sector functions. Building and construction equipment without machine control will certainly end up being a distant memory and the benefits obtained from it will certainly be various.

Trimble equipment control systems offer a myriad of advantages to any individual that utilizes earthwork equipment and, at EarthCalc, we can offer you with 3D declare your equipment control-enable devices. Not exactly sure if machine control is worth the price? Consider the adhering to factors why you require to consider this option.

Making use of general practitioner aligned with your 3D layout documents, these systems basically ensure that you will eliminate or place the appropriate amount of product at the building site. On the majority of construction sites, revamp is a common and irritating reality, but with Trimble machine control, you can eliminate the demand for rework.

A Biased View of Sheroz Earthworks

Usually, with Trimble equipment control, you can remove excess equipment at a details work site. A job that may have called for the usage of 3 or four pieces of digging deep into equipment now might require only 2 pieces of tools to complete the very same task in much less time. This permits you to move your tools to an additional work site and manage numerous jobs at once.